In the hand model making industry, vacuum silica gel complex mode is often used for small batch copying. Because the cost of the silicone mold is low, the production cycle is short, and it has a very good market competitive advantage. so in many industrial products, In the early stage of the mold, the vacuum silicone compound mold will be used to meet the needs of the product structure design inspection and the market development of the exhibition orders.

Vacuum moulding is using a product prototype under vacuum to produce a silicone mold under vacuum conditions, and using the mold under vacuum conditions (PU, transparent PU, POM-like, POM, ABS) and other materials, casting and forming the same copy of the product prototype. The parts can reach the strength and hardness of ABS and other materials, and can also be remolded together according to the customer’s required configuration colors. Because of its fast speed and low cost, it has solved the cycle and cost of new product R&D of the company.

Three simple steps for vacuum mold making:

- Prototype: Before making the CNC silica gel prototype, you need to make a prototype. The prototype can use the more common ABS material, CNC machining can be.

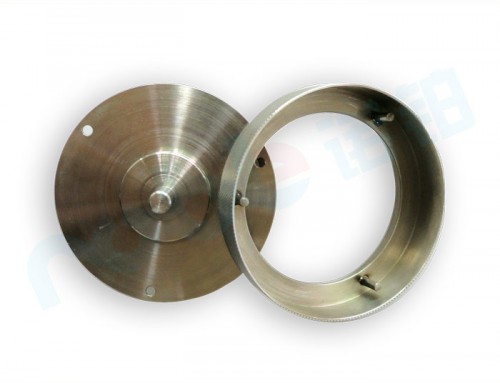

- Silicone mold: After the prototype is ready, silicone molds are produced. After eight hours of drying, the silicone mold was cut open and the prototype was removed. At this point the silicone mold is ready.

- Injection type: The liquid gum material injected into the silicone mold, can be dried. Transparent silicone mold life of about 20 times.

Step1: use CNC, SLA, or mud carving to make prototypes and make nozzles

Step 2: Surround the prototype with the board and prepare for the mold

Step 3: Pour the vacuum liquid silicone into the mold with a vacuum machine to cover the entire product.

Step 4: Bake the mold in the oven to accelerate the curing of the silicone mold.

Step 5: Take the prototype out of the mold

Step 6: According to the material needed for the product, vacuum the material and copy the finished product

In addition to being able to produce in a vacuum complex mode, it can also be machined by CNC. Noble is a professional machining manufacturer with enough experience to produce.