Noble Platinum Chi made: Aluminum alloy by adding other metal elements into the aluminum obtained a metal alloy, such as silicon, iron, copper, aluminum, etc., to join other metals have low density, high strength, corrosion resistance, etc. Features, its light weight and strength characteristics make the aluminum alloy is widely used in various parts manufacturing, such as automotive wheels, aviation parts and other technology and life is not difficult to see the existence of aluminum alloy parts, We come to understand the aluminum alloy parts is processed through which way, the common parts of aluminum alloy processing have?

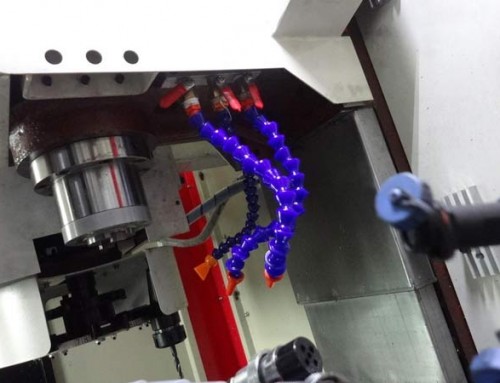

1, machining of aluminum alloy parts, also known as CNC machining, automatic lathe machining, CNC lathe processing,

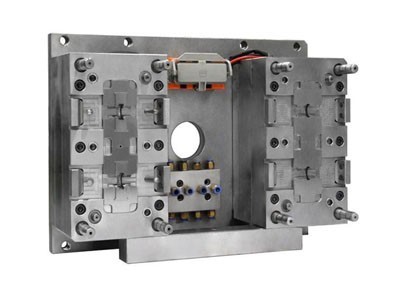

(1) mold, mold, drill, grind and other general-purpose machine tooling mold parts, and then fitting the fitter to assemble a variety of molds.

(2) high precision mold parts, only ordinary machining difficult to ensure high machining accuracy, which requires the use of precision machine tools for processing.

(3) In order to make the mold parts, especially the complex shape of the punch, die cavity and cavity processing more automated to reduce fitter fit workload, the need to use CNC machine tools (such as three coordinate CNC milling machine, machining center, CNC grinding machine Other equipment) processing mold parts.

2, aluminum parts stamping machined

Stamping by presses and molds on the plate, strip, pipe and profiles such as the external force, so that the plastic deformation or separation, so as to obtain the desired shape and size of the workpiece (stamping parts) forming method.

Stamping is the use of conventional or special stamping equipment, power, so that the sheet metal directly in the mold by the deformation force and deformation, so as to obtain a certain shape, size and performance of the product parts production technology. Sheet metal, mold and equipment are three elements of stamping. Stamping is a metal cold deformation processing methods, it is called cold stamping or sheet metal stamping, referred to as stamping. It is one of the main methods of metal plastic processing.

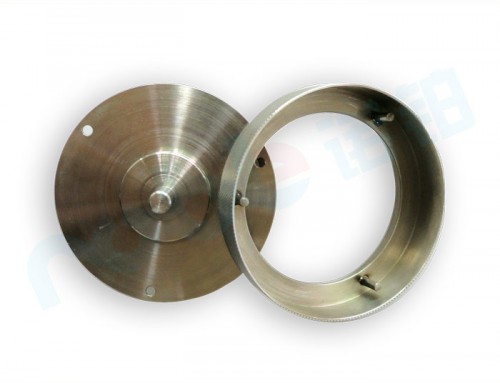

3, precision casting aluminum parts

Precision Casting, is a special casting. Parts obtained by this method generally do not need to be machined. Such as investment casting, pressure casting. Precision casting is a casting method relative to the traditional casting process. It can achieve relatively accurate shape and high casting accuracy. More common practice is: First of all based on product design requirements (leaving a very small margin or leave no margin) of the mold, cast wax casting method to obtain the original wax model; repeat the wax coating mold and sanding Process, curing the shell and drying; and then dissolving the internal wax mold, is dewaxing to obtain a cavity; roasting the shell to obtain sufficient strength; pouring the required metal material; clearing the sand after shelling to obtain High-precision finished product. According to product needs or heat treatment and cold work.

4.aluminum alloy powder metallurgy

Powder metallurgy is a technology used to make metal powders and to make materials or articles from metal powders, sometimes with small amounts of non-metal powders, after mixing, forming and sintering. It consists of two parts, namely: (1) manufacture of metal powder (also including alloy powder, hereinafter referred to as “metal powder”). (2) Materials (referred to as “powder metallurgy materials”) or products (referred to as “powder metallurgy products”) are manufactured from metal powder (sometimes with a small amount of nonmetallic powder added) as a raw material through mixing, shaping and sintering.

5, aluminum parts injection molding

The solid powder is uniformly kneaded with an organic binder and granulated. The granulated material is then injected into a cavity of a mold by heating and plasticizing (~ 150 ° C), and the resulting mixture is cured and then chemically or thermally decomposed Of the binder removal, and finally densified to obtain the final product. Compared with the traditional process, it has the characteristics of high precision, uniform organization, excellent performance and low production cost. Its products are widely used in electronic information engineering, biomedical devices, office equipment, automobiles, machinery, hardware, sports equipment, Weaponry and aerospace and other industrial fields.

Of course, in addition to the above-mentioned five common aluminum alloy parts machining methods, there are special processing, laser processing, EDM, ultrasonic machining, electrolytic machining, particle beam machining and ultra-high speed machining. Not listed here one by one. In addition to the above-mentioned aluminum alloy parts processing and forming process, the processing of aluminum alloy parts also involves the surface treatment process, including anodizing, electroplating, etching, etc., Nobel would like to introduce to you next time.

Novo Platinum Chi-made more than 10 years has been focused on CNC machining, for all types of domestic and foreign enterprises to provide aluminum batch processing, metal parts batch processing, precision metal parts processing, metal parts batch processing, machining robot parts such as high quality and efficient CNC machining service.

![[Noble Platinum] CNC Lathe Knife Operation Prone Problems](http://www.china-cncmachining.com/wp-content/uploads/2017/11/thirteen-e1511323361490-500x383.jpg)