1、Painting and machining: The hardware factory adopts the paint machining when producing large-scale hardware products, and the hardware avoids rust through painting process, such as: daily products, electrical enclosures, crafts, etc.

2、 Electroplating: Electroplating is also the most common machining technology for hardware machining. Electroplating is performed on the surface of the hardware through modern technology to ensure that the product does not become embrittle during prolonged use. Plating processes are common: screws, stampings, Cell, turning parts, trinkets, etc.

3、Surface polishing: The surface polishing process is generally used in daily products. Through the surface burr machining of hardware products such as: We produce a comb, the comb is made of stamping hardware, then punch out the comb corner It is very sharp. We must throw the sharp edges of the corners into smooth faces through polishing. This will not harm the human body during use.

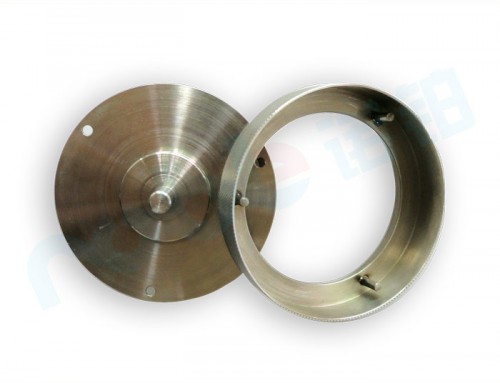

Turning the outer circle is the basic method for machining the outer and inner round surfaces of metal machining. The equipment used is a lathe. In a general machinery factory, the lathes account for about 40% of the total number of machine tools. Turning is the main method of rough machining and semi-finishing the outer surfaces of various materials, and it is also the final finishing method of various materials that should not be ground.

In single-piece production, the turning outer surface is usually carried out on an ordinary lathe. In mass production, multi-tool semi-automatic lathes or automatic lathes are widely used. Large disk parts should be processed on a vertical lathe. Large long-shaft parts need to be machined on heavy-duty horizontal lathes.

The characteristics of turning outer surfaces are:

1, the tool is simple, manufacturing, sharpening and easy installation;

2, smooth cutting process, small fluctuations in cutting force, is conducive to the use of high cutting speed, increase productivity;

3, the machine has good versatility, can be processed in a fixture in the outer circle, face, inner hole, thread and chamfering. The mutual position accuracy between surfaces is easy to guarantee;

4, suitable for non-ferrous metal parts finishing.

BY NICOLE