Service

- Structure design optimization.

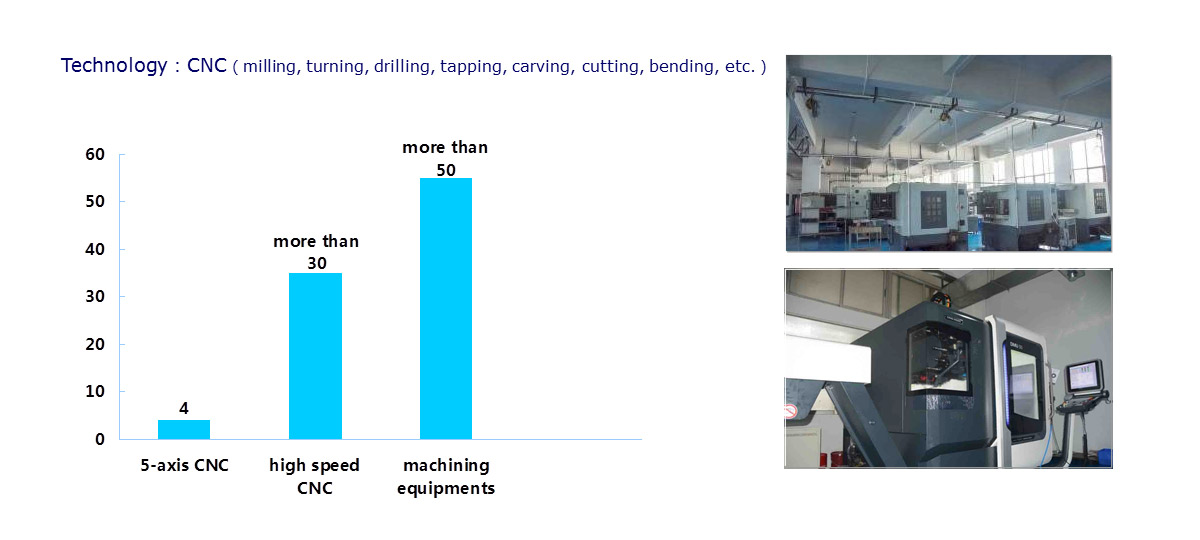

- CNC machining: we have all CNC processes to make different kinds of parts.

- We have powerful industry resources integration abilities, to provide convenient and perfect service for clients, we have integrated following manufacturing resources:

- Compared with your contacting corresponding venders directly, we will provide the same price but better service to ensure delivery and quality. Choose us and you will enjoy convenient and guaranteed one-stop service.

- CNC Machining Center: Milling, drilling, turning, threading, tapping, boring, facing, spotting, counter boring.

- CNC Milling: High precision milling, numerical control carving and milling, CNC engraving and milling.

- CNC Bending: Bending-High precision seamless bending, sheet metal bending.

- CNC Punching: Punching/stamping High-precision Sheet Metal Fabrication.

- Welding: GMAW Welding, MIG Welding, Laser welding.

- Laser cutting: High precision cutting.

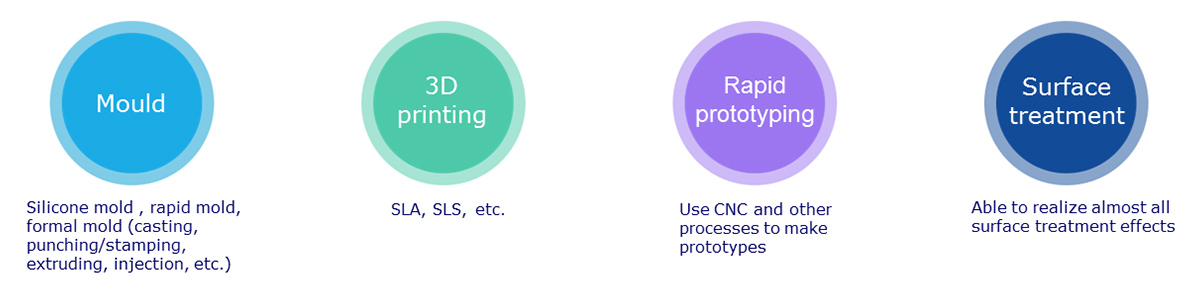

- Molding/Tooling: Rapid Tooling, die-casting, Extrusion molding, Silicone mold vacuum casting, etc.

- 3D printing: SLA, SLS, FDM.

- Obey the secrecy control process strictly and specify the perfected and detailed security process, which can sign NDA according to client’s requirements.

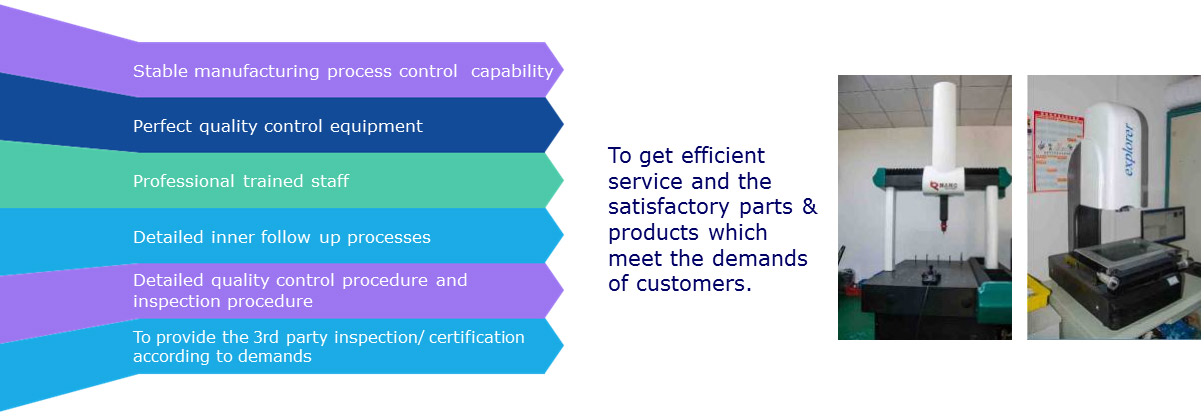

We have Rich experience and Professional team, so we can offer you the Lowest Price in the same quality, we can provide you with Perfect Quality, Accurate Delivery and Complete Supporting, We are good at machining the Complicated Parts with curved surfaces.

We can make parts for you with all kinds of metal and plastic materials

- Metal: aluminum, aluminum – magnesium alloy, aluminum – zinc alloy, copper, brass, bronze, stainless steel, SUS303, SUS304, 45# steel, iron, Galvanized steel sheet, sheet metal, SPCC, etc.

- Plastic: ABS, acrylic/ PMMA, PP(Polypropylene), PC(Polycarbonate), PU (Polyurethane), POM (Delran, Acetyl), PVC, PE (Polyethylene), PA (Nylon, Polyamide) PEEK, Chemical Wood, etc.

Quantity:

- From 1 off prototype to 10000+ mass manufacturing.

Dimension:

- From one block solid material, the largest dimension is 1200mm

- If you accept splitting, there is no dimension limit.

Tolerance:

- Metal parts: ±0.01mm;

- Plastic parts: ±0.05mm

We can provide almost all kind of surface treatment, such as:

- Mirror anodizing: By buffing and anodizing process to form mirror like finish.

- Common anodizing: Anodizing layer=10um, color can be customized.

- Hard anodizing: Anodizing layer≥40um, color can be customized.

- Drawing/brushing: By brushing and chemical process to form shining with line.

- Oil / Baking Paint: Color can be customized.

- Powder coating: Form a thick layer protect the surface, good corrosion resistance.

- Polishing: Finish of aluminum itself, shine metal.

- Electrophoresis: Based on anodized process, an extra transparent film makes the surface clearer and look bit of shining, good corrosion resistance.

- Sand blasting: Making the surface roughness and cleanliness, improves the fatigue resistance and adhesion strength of the artifacts.

- Other finish treatment: grinding, screen printing, pad printing, laser engraving, electroplating, UV coating, etc.

- Note: Please give us the details as possible as you can. Such as the colors standard (with Panton numbers or CMYK&RGB numbers), the size of sandblasting, the size and the location that you want for screen-printing, etc. If you don`t know how to prepare them, please contact us for help.

Drawings format:

- 3D: step/STP, IGS, PRT, SLD, etc.

- 2D: DWG. pdf. CDR. AI, and the other format.

Software:

- 3D software: Pro-e (CREO), UG, Solid works, Catia, Rhinoceros, 3dmax etc.

- 2D software: AutoCAD, Photoshop, CorelDraw, Adobe Illustrator etc.