3D printing is being used by more and more automotive applications. It can be applied to all applications from internal components to the entire chassis. Even tires can be printed in 3D. This technology has many advantages, including lighter parts, less scrap, faster manufacturing time, lower costs, and more. However, some cars have poor 3D printing results. Because 3D printing is a layer-by-layer process, the final product often shows these layers.

Of course there are exceptions. Some materials and post-processing techniques essentially eliminate any signs of layering in glass and plastic parts. But in general, 3D printing is not the technology of choice for achieving a perfectly clear surface. For this reason, most manufacturers turn to CNC machining. CNC machining sculpts objects from solid blocks, so there is no layer line to produce clear components that can be used in headlights, taillights, or interior lights in cars.

Car lights are usually CNC machined from polymethyl methacrylate or PMMA (also known as acrylic glass). Its light weight and shatterproof make it ideal for automotive applications. And it is clear that machining it will not affect quality.

Chinese company NOBLE carries out 3D printing and CNC machining at the same time, and offers a wide range of CNC machining services, including milling, turning, electric discharge machining (EDM) and wire cutting processing and surface grinding. The company has sophisticated 3-axis, 4-axis and 5-axis CNC machining centers to meet customer needs, including automotive applications.

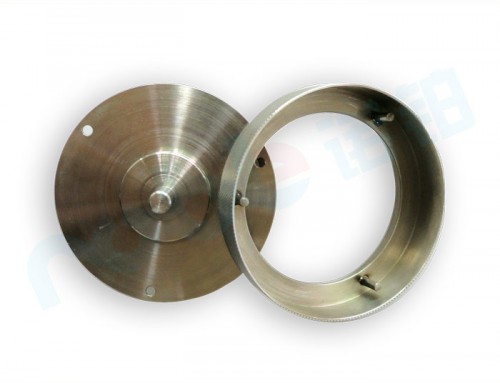

Carburetor casings, suspension parts, axles, bearing covers and engine casings are all manufactured using CNC equipment. Acrylic/acrylic PMMA processing for car lights, exterior lights, and interior lights is another example of how CNC machining can be used when the automotive industry produces components.

The advantages of CNC machining in automobile manufacturing include multi-axis linkage to achieve the tortuous processing of prototype machining; high accuracy and good product consistency; high degree of automation, resulting in low labor intensity; and NC also ensures simplicity and efficiency.

In addition to NOBLE’s selection of advanced equipment, the company also has experienced engineers who can handle complex and precision components in a variety of industries including automobiles. It also provides quick turnaround time – on average it can return quotes within 24 hours.

Therefore, although 3D printing may be taking over more and more automotive industries, it cannot be completely taken over. CNC machining has a place in the automotive industry and will not be abandoned within a short period of time. Automotive lighting is just one example of the obvious advantages of CNC machining, but as we have seen in many cases, 3D printing and CNC machining complement each other, and the cooperation between them is better than separation.