In recent years, the rapid development of automation equipment, as a cnc processing technology, has good processing performance, can process complex parts of different shapes of parts, to produce high-quality parts. Many industrial production enterprises are CNC machined parts. CNC parts processing is a reduction of processing, the main part of the raw material is removed, is the most commonly used in modern machining a way that can be a very good solution to complex, sophisticated, small quantities, changing parts processing Problem, the following to introduce the advantages of cnc parts processing:

1. Can reduce the number of tooling, the ability to shape complex parts do not require complex tooling, if you need to modify the size and shape of the part, only modify the part of the processing procedure on it, for new product development and improvement.

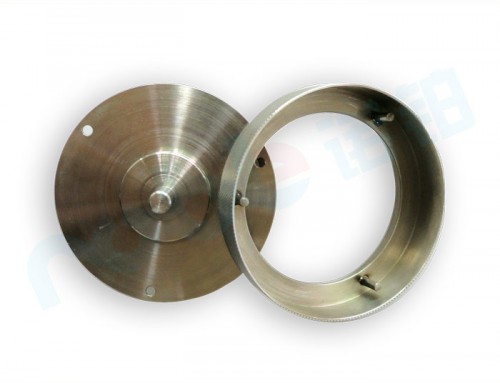

2. Using CNC machined parts of good quality, high precision, suitable for processing of various parts requirements.

3. Parts of more variety, small batch processing of production efficiency will be relatively high, can effectively reduce the machine adjustment and process inspection time, but also due to the use of cutting volume and reduce cutting time.

4. Can process more complex profiles, and even can process some unobserved processing sites.

CNC precision parts processing In order to improve the cutting performance, both at home and abroad have developed wire cutting machine copper wire, some of which are within the brass wire, the lower the melting point of the zinc alloy, the fire discharge greater vaporization power, is Wire cutting cutting speed is higher, the specification is (0.10 ~ 0.30) mm; Similarly, when cutting fine grooves or smaller fillet, you can use tungsten wire or molybdenum wire, the minimum diameter of up to 0.02 ~ 0.06mm.

BY ICY ZOU