What are the characteristics of CNC prototype machining?

CNC prototype machining using materials: ABS (transparent ultra-high temperature, black, imported, domestic and so on), POM (Saigang), PMMA (Acrylic), MC (Nylon), PC, PP, PA, BT, PVC, aluminum alloy, copper and so on. After the workpiece is clamped one time, the digital control system can control the machine tool to automatically select and change the tool according to different processes, and automatically change the spindle speed, feed amount, tool trajectory and other auxiliary functions of the tool spindle, and complete several workpieces in turn. On multi-process processing, the entire process is automatically controlled by the program, without the operator’s human factors.

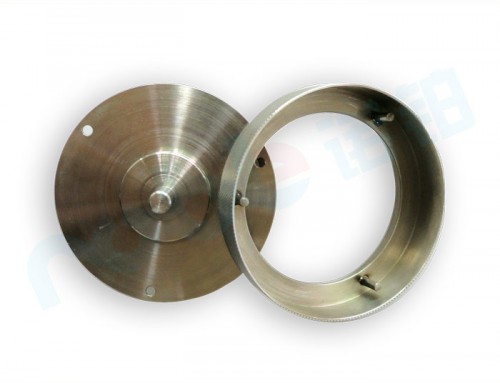

Aluminum alloy hand model production process:

1, CNC computer. Through the CNC machining equipment according to the path set by the program, changes are made on the basis of the raw material of the product to get the prototype of the aluminum alloy hand board model.

2, Manual machining. After the prototype of the aluminum alloy hand board model comes out, the appearance of the sample will have some burrs and excess corners, the staff should use sandpaper to polish, so that the appearance of the aluminum alloy hand model becomes smooth and delicate.

3, Laser engraving, which is to use laser technology to remove the appearance of the sample paint, make part of the sample position translucent.

4, Oxidation, anodic treatment, is the function of electrolysis. Because the corrosion resistance formed after the treatment is poor and the hardness is low, the cost of the website is very low. Therefore, it is rarely used in the process.

5, drawing, that is, in the appearance of aluminum alloy pull out a thin line, so that the processing will make the sample better texture.

Problems to be Noted in CNC Machining Processes:

(1) Determine the processing content of the CNC machining center, determine the installation base surface, the machining base surface, and the machining allowance of the workpiece, and arrange the processing procedures for the purpose of making full use of the efficiency of the CNC machining center.

(2) For complex parts, due to thermal deformation in the machining process, internal stress generated after quenching, and deformation after the part is pressed, etc. It is difficult to complete the entire process after one clamping. It can be considered twice or more times.

(3) Arrangement of processing procedures should be based on the principle of gradual refinement. First, arrange heavy cutting and rough machining, remove the machining allowance on the blank, and then arrange the content with low processing accuracy.

(4) Large-flow cooling method is adopted. In order to reduce the influence of a large amount of heat generated during processing on the machining accuracy, in order to increase the tool durability, it is necessary to actively adopt a large-flow cooling method.