First, the CNC machining center knife method

In simple terms, CNC machining centers commonly used knife method on the knife on the knife, automatic knife and cut the knife and so on several methods. As a complete processing of a workpiece may involve several or even dozens of tools, due to the original test cutting method, and the poor accuracy of the knife, it is rarely used. We focus on the first two kinds of the more typical method of knife:

1, automatic knife method

The automatic tool setting is realized by the tool detection function configured by the CNC machining center. The device can automatically and accurately measure the length of each tool in each coordinate direction and can automatically correct the tool error value. The entire testing and correction process can be performed on the machine tool On the basis of normal operation. This knife method is entirely electronic control device to achieve, eliminating the human error on the knife, so the knife accuracy is higher, the knife efficiency is better.

2, the knife on the knife method

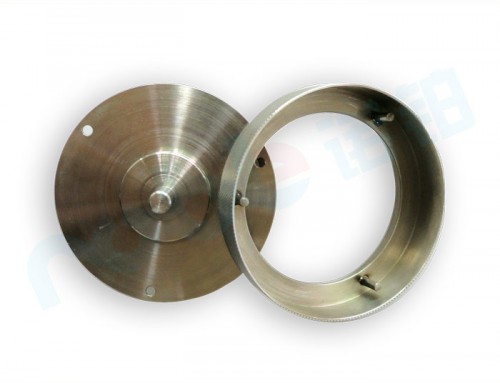

Tool on the knife on the knife, because of its higher economy, is now the main method of CNC machining center knife. The knife is divided into the inside of the knife on the knife and the knife outside the knife on the knife two. Outside the knife tool on the knife need to pre-calibrated outside the machine, and then put the knife on the machine can be used; Machine tool on the knife is the tool is installed directly on the machine at a fixed position on the measurement method .

Second, the knife error prevention measures

Due to the variety of tools used in CNC machining centers, the size of the tools is also very uneven, so the knife should be based on the actual processing conditions, choose a good tool to determine the program instructions, enter a good tool parameters and tool offsets. Even so, different tooling methods may also have some errors, thus affecting the accuracy of the workpiece machining.

When using the tool setter, the tool setter and the automatic tool setting, the error is not due to the manufacture, installation and measurement errors of the instrument, and the inaccurate use of the instrument can also cause errors. Therefore, to pay attention to the accuracy of the instrument installation and measurement, more importantly, to grasp the correct method of using the instrument, only the correct use and operation, in order to lower the error down. At the same time, the quality and rigidity of the tool as well as the accuracy of the machine itself is also the reason that affects the tool setting error, so it is also very important to select the qualified tool and check the zero drift of the CNC machining center regularly.